Mounting Canvas to substrate–producing an excellent option for framing a Canvas Print

- At March 16, 2015

- By paul

- In Articles/Reviews, Printing & Framing

1

1

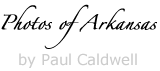

When print makers think about canvas, they tend to think about stretching. It also means that the print maker has to either pay someone to stretch the canvas or take on the training to learn how to stretch. However it’s possible to produce canvas prints which can can be turned into beautiful framed prints without stretching and they can be displayed without any glazing (glass) like a paper print needs. This is done with a wet mount of a coated canvas to a substrate such as gator board. In the photograph above you can see a 28″ x 28″ canvas print that was mounted to gator and has been framed.

What is Gator board and why not just use foam core?

- Gator board has a much more durable surface, and can take a wet mount without damage. By design gator is very stiff and comes in various thicknesses. I choose to work with 3/16″ and 1/2″ for my work. Gator will not deform over time and will resist bending and due to the stiff nature of the product it will not show any rippling when the canvas is mounted.

- Foam core is not a great solution as it’s much softer by design and will easily allow a pressure dimple or other type of damage to the print. Foam core also will not work well with a wet mounting type solution as it will tend to separate and warp if it gets moist. Most foam core doesn’t have a perfectly even surface and thus will not allow for a print to mount well.

For this type of mount, you need to make sure you have coated your canvas as the application involved a wet mounting process. So if you are using Crystalline or any “glossy” canvas which is aqueous based, you can’t allow any water to get on the face of the canvas. If this happens, then the ink will more than likely wipe off as you clean the print. For my work, I use both Breathing Color’s 800M matte canvas and Crystalline. Before I get ready to mount, I will coat the canvas with Breathing Color’s Timeless glossy coating. This will protect the print during the mounting process and add years of protection to the print.

Once I have the canvas coated, I will trim it to the final size for mounting. I prefer to leave a 1/2 inch border on the canvas to allow easy handling of the canvas during the mounting. So I quickly make a set of tick marks around the print and trim it down to size. For example on a 20 x 30 canvas, I will have a canvas that is 21″ x 31″ and I make the Gator board the same size. This means you do have a bit of extra waste but to me the extra is worth it since the 1/2 border means I have some room to handle the print without getting my fingers on the face of the print. Click on the individual images to view them larger.

- Measuring your canvas for the final trimming

- Making the final trim leaving only a 1/2 inch border

With the canvas trimmed, you are now ready to prepare the gator board. Gator comes in white or black, I use black, simply because I use a white glue and it’s much easier to see the board with glue on it to make sure you have 100% coverage. For our 20″ x 30″ print, which is still 21″ x 31″, I have cut a 3/16 inch piece of gator to the same size of 21″ x 31″. I will always wipe off the gator with a damp rag. This helps to set the glue to the board and remove any small particles that may be sitting on top of the gator. Then I will lay out the glue. I use a brand called Miracle Muck. This is a fast setting water based glue that has excellent adhesion properties.

For this process, I start with 2 large spots of glue towards the center of the gator. With a soft burnishing brush, I will then start to layout the glue evenly across the gator. While doing this, you want evenly distribute the glue across the face of the gator board. I tend to make a series of passes, going up and down and then across the face of the gator board. In the series of pictures below you can see how this looks. I use a standard 4 inch print maker’s roller to layout the glue. This roller has a soft gum rubber finish, not a hard one. I prefer the 4 inch roller for all sizes of gator board as I feel I get better control over the distribution of the glue. When you are finished rolling, make sure you take the roller to the sink and wash off the glue as it will start to set quickly.

- Glue ready to be spread on black gator

- Starting the process of glue distribution

- Gator ready for canvas print to be applied

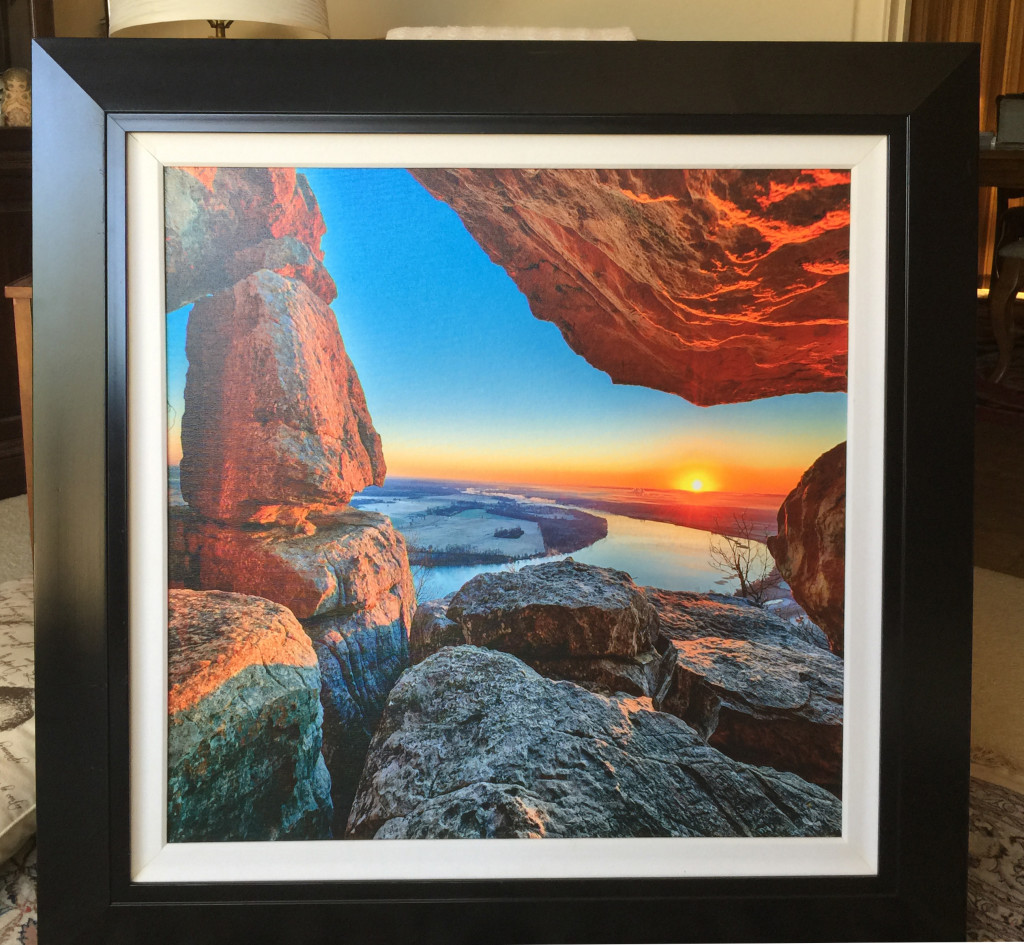

Before we go to the mounting of the canvas, let me briefly talk about the tools I use. In this image you can see a close up of the two rollers I use and the soft tack/lint free rag.

- The soft roller is made from black gum rubber and is found in most art supply stores. It’s called a burnishing brush and most commonly used in lithography and print making. I have found it to be indispensable for the process of rolling out the glue. You can pick these up in various widths but I prefer the 4 inch size for all my work. Over time the material of the roller will harden and crack, so expect to replace this roller in a year or so.

- This item is a hard roller and I use this once the print has been placed on the glue prepared gator board surface. This roller is around 8 inches wide applies a nice even pressure to the face of the canvas to make sure all the air bubbles have been removed. The key to this type of roller is the metal frame. Make sure you get one with a stiff frame that won’t bend, or the roller will bind up under pressure.

- The last item is a lint free soft rag, most commonly found in a auto parts store. In the process of mounting I will use this rag many times. To help lay down the canvas and then to clean up any excess glue that might have slipped up to the face of the canvas. You want to use this rag damp, as a dry rag may lightly scratch the face of your canvas.

As soon as you have the gator board covered with glue, you want to start the mounting process. This is the most critical part so take some practice runs on smaller prints, before you try to mount an image larger than 16″x 20″. The glue I use has a working time of about 5 minutes, after that, if you don’t have the print down flush, you will need to pull the print off, and re-lay down your glue. Remember back when I first trimmed the print, I left a 1/2 inch border. This allows you a bit of room for errors and more importantly, you can pick up the print without worry of getting your a glue print on the face.

In the gallery of images provided below I have show a series of pictures that apply to the steps I have listed here:

- Take the print and roll it up so the side to be mounted is outside. Then line one of the edges of the canvas to the gator board edge. It’s much easier to work with the print rolled up than trying to lay it down in one large step.

- With your damp rag, on the face of the print (NOTE: if you are using a glossy canvas, you must coat it first) unroll the print and at the same time apply some light pressure to the face of the print. With one hand control the roll of the print and with the other smooth out the print over the gator board.

- Once you have the print all the way rolled out, take your hard burnishing roller and start at one end of the print and roll across the face of the print. Apply a considerable amount of pressure during this step as you will not hurt either the print or the gator. Again this will take time to get the hang off. But this step is very critical as you don’t want any air left under the canvas. Once you have finished, take you damp rag and wipe over the face of the print just to feel for any bumps. This is more important on a large print of 24″ x 36″ or larger.

- Once you feel the print is down evenly, pick up the gator board and hold the mounted print in the light at an angle and look for any bumps or problems on the face, as now is time to get them out. If you see some trapped air, just get your damp rag and work it out. It you see a piece of trash, you will need to pull the print back, remove the debris and then re-burnish. If you do this within the first 5 to 6 minutes the glue will still set, but if wait any longer, you may need to re-apply some glue on the board. Also look to see that you don’t get some glue on the print or have wiped a bit of washed down glue over the face of the print. This is easy to get off now, but next to impossible once allowed to dry.

- When you are done, you print should look like this. You may see that the gator board has bowed up due to the moisture, but don’t worry as during the drying process this will all come out. Plus since the mounted print is going in a frame, if you see a bit of bowing still after drying, do not worry as the frame itself will even the print out.

- 1. Roll up the print and align with one edge of the glue covered gator

- 2. Continue to un-roll the print on the gator

- 3. With the print down use your burnishing roller to apply pressure to remove air

- 4. View the mounted print at an angle to the light

- 5. Finished 20 x 30 canvas on gator print

Do a quick check on the back of the print to make sure you don’t have any globs of glue there. This is just a nice way to finish the piece front and back.

If the print is a 2o x 30 or larger, I like to place some weight on the face of the print while it dries, just to help keep the bowing to a minimum.

I like to let the prints dry overnight, but if you are in a push you should be to trim the piece after about 6 hours. Just take you finger and pull back on the edge and see if there is any play with the canvas. It should totally resist any attempt to pull it back if the glue has dried.

Now all that is left is the trimming, and this can also be a bit tricky. Gator board is much stiffer than foam core and even 3/16 inch will require several cuts. What I like to do is use a ruler, lined up on the white border, and using fresh blade in a olfa hand cutter make my cuts. These cutters have a segmented single blade and you can easily break off the dull tip and keep on cutting. You don’t want to to use a blade on too many cuts as gator board will dull a blade quickly. The process I like to use is as follows:

- Line up the straight edge along the white border, and make your cut all in one even pull. The first couple of passes will cut the canvas and start to break into the gator board. I always make sure to cut into a cutting mat. These are designed to absorb the point of the blade and help you control the cut. You can see the green cutting mat in the picture.

- After you have made the cut down into the gator board, you will start to see the smooth way the gator board has cut away and given you a clean edge. If I am working on prints that I know are going into frames, I will go ahead and snap the gator board after 2 cuts. You can see in this picture as I am pulling the cut gator board away which shows the clean cut.

- On a larger print, you may want to tape down the ruler, as it’s easy to have the ruler move just a bit as you move down the print. On 20″ x 30″ prints or larger I always do this. There is nothing worse than getting all this work done up to this point to have an errant blade cut into the print and ruin it. Take your time on this part. Also be aware that cut gator board edges are very sharp and by running you hand over them, you can get a cut pretty quickly.

- The finished mounted print is now ready to put into a frame. I will often blacken the upper edge of the print as you can see the white line of the canvas against the black of the gator.

- 1. Making the finishing cut against a ruler

- 2. A view showing the clean cut edges

- 3. Taping the ruler down can help to keep longer cuts lined up.

- 4. A finished mounting of a 20 x 30 canvas print

This is a great way to get into canvas printing, and not have to focus on stretching. The finished product in a black frame is show below.

Doug Dolde

Paul,

Interesting article but I’d make a suggestion in line with what I do.

I use the Miracle Muck also but coat the board (usually 8 ply mat board) with the Muck evenly with a foam roller and maybe even use several thin coats. Once it is dry I place the canvas on the coated board then put them in my Seal 160 press at about 180 degrees. I have to do it in sections for a large print but there’s no issue with that, you can’t see where it is done.

The Muck is heat activated and bonds securely with about one minute in the press. I do the Timeless coating after the mounting is finished.

Just my $.02. Seems much easier than what you’re doing.